According to the maintenance mode of liquid coupling, vertical coupling can be divided into common type, the vertical hydraulic coupling moment type hydraulic coupling and variable speed; according to the drive type, vertical hydraulic coupling can be divided into direct drive and parallel drive two; according to the installation location and power coupling, vertical hydraulic coupling can be divided for sitting and hanging up two. A vertical hydraulic coupler that can be installed vertically and vertically is called a vertical hydraulic coupling. Its classification and characteristics are as follows:

The speed regulating hydraulic coupler is restricted by the structure, only the hanging vertical is not sitting upright, that is, the motor is above the coupler and the working machine is under the coupler.

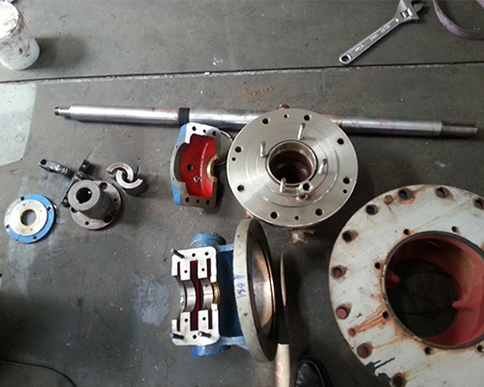

The structure characteristics of vertical hydraulic coupling on the surface, it seems that the horizontal vertical hydraulic coupling hydraulic coupling up, the need to strengthen the sealing end of the coupler downward. When the horizontal coupler is working, most of the working liquid works in the circular circular diameter, so the possibility of the leakage of the main axis of the spindle is small. When vertical coupling is installed vertically, the possibility of the working liquid leaking down is more likely due to the effect of gravity. In order to prevent leakage, a reliable seal structure must be used, and there are also the lower end of the shell.

When working overload, large circulating motion of working fluid can be quickly discharged into the auxiliary cavity below by means of dynamic pressure and gravity, so that motor and working machine can be protected from overload in time. If the auxiliary cavity is above, the direction of liquid flow is opposite to that of the auxiliary cavity when overloaded. It is necessary to rely on static pressure and overcome gravity to push the liquid to the auxiliary cavity above, so its discharge speed is slow. The hydraulic filter element at dawn is not as sensitive as the coupler under the auxiliary cavity. Plug and fusible plugs shall be arranged in the above. For the convenience of the gas and gas plug and remove fusible plug, the fusible plug should be located in the above. At the same time, the oil slug should also be set in order to replace the oil. Usually the position of a vertical coupler is exactly the position of 80% oil filling.