Shenyang German Machine Hydralic Transmission Machinery Co., Ltd.

Contacts:Sun Manager

Mobile phone:13804900881

Telephone:024-31309368

Fax:024-31309368

Address:No. 14 Shen Da Road, Shenyang flood diversion area

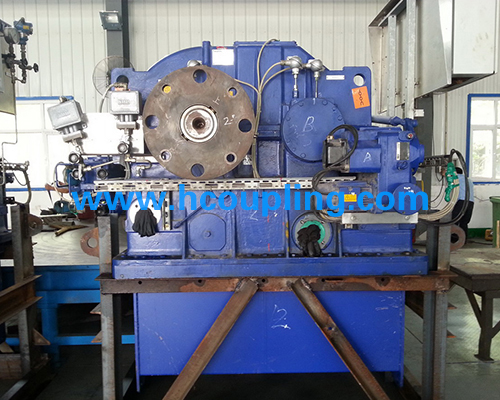

Coupler maintenance

The maintenance contents include the overall maintenance and maintenance of the equipment, the inspection of the pipeline, the replacement of the vulnerable parts, the replacement of the spare parts and the installation and commissioning of the equipment.

The coupling uses liquid oil as the working medium to transfer the kinetic energy of the liquid through the pump wheel to the mechanical energy connection motor and the working machinery to realize the transmission of power. It has a no-load starting motor, stable stepless speed etc., for power plant feedwater pump speed regulation, can simplify the boiler feedwater control system, reduce the number of high pressure valve, because through the speed change water and pressure to meet the unit start stop and load change, good regulation characteristics, the valve pressure drop is small, line loss that is not easy to damage, so that the water supply system to reduce the fault, when the water pump jam and seizure occurs, the pump and motor can play a protective role. Therefore, in the modern power station, the water pump with hydraulic coupling is widely used in the boiler feed water pump. The main components are the pump wheel, the turbine, the rotating shell, the input shaft, the output shaft and the spoon pipe. Usually, the rotation of the shell and the pump wheel are connected to the flange in the flange. Pump wheel and turbine wheel blades are called work, two, two are respectively connected with the input and output shaft, there is a gap between them, so the pump and turbine has the same radial size, cavity shape, together to form the oil chamber, the oil from the pump into the wheel, and follow the power machine rotates together, the role of oil under the centrifugal force, was thrown to the outside of the pump wheels, turbine blades forming high speed oil flow into the opposite direction, gradually slow down and flows back to the inside of the turbine inside the pump wheel, constitute an oil cycle. The absolute flow of a working liquid in a working cavity is a three-dimensional motion. When the rotating shell is connected with the pump wheel, it is surrounded by the turbine so that the working liquid can be stored in the pump wheel. The input shaft is connected with a power machine (such as a motor), and the output shaft is connected with the driver (such as a pump). The characteristics of hydraulic coupler is to eliminate shock and vibration; the output speed is lower than the input speed, two speed difference increases with the increase of load; overload protection performance and good starting performance, while the load is too large to stop when the input shaft can rotate, not to damage the machine; when the load is reduced, the output shaft speed increase until close to the speed of the input shaft, the transmission torque tends to zero. The transmission efficiency of a hydraulic coupling is equal to the ratio of the speed of the output shaft to the speed of the input shaft. Higher efficiency can be obtained when the speed ratio of normal hydraulic coupling in normal operating conditions is more than 0.95. The characteristics of a hydraulic coupler vary from the shape of the working chamber to the pump wheel and the turbine. It generally depends on the natural heat dissipation of the shell and does not need the supply of external cooling. The process of the transmission of a hydraulic coupler can be regarded as a process of joint force.