Shenyang German Machine Hydralic Transmission Machinery Co., Ltd.

Contacts:Sun Manager

Mobile phone:13804900881

Telephone:024-31309368

Fax:024-31309368

Address:No. 14 Shen Da Road, Shenyang flood diversion area

Coupler maintenance and maintenance:

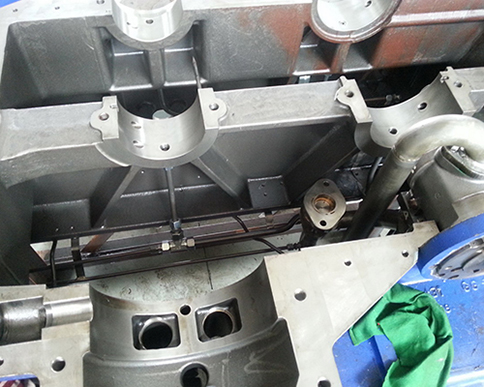

Hydraulic coupling is a transmission device that transfers power by oil pressure. Because the size of the oil pressure is not restricted by the grade, it is a continuously variable speed shaft coupling. The working process of the hydraulic coupling: the hydraulic coupling is mainly composed of the pump wheel, the turbine and the rotating shell. The pump wheel and the turbine are the same size and are arranged in the same direction. There are many radial blades in the cavity, and the number of the turbine is generally less than 1 or 4 pieces less than the pump wheel to avoid resonance. The main shaft of the pump wheel is connected with the main shaft of the motor (or the first speed gear shaft), and the turbine shaft is connected with the main shaft of the pump (or the gear shaft of the second speed increase).

1) the function of slowing down the start and isolating the torsional vibration

When the machine is stationary, there is a gap between the components in the transmission system, so the flexural member is relaxed, so the torque applied to the motor at start-up instant is very small. When the motor quickly accelerates, because the clearance of the transmission element is eliminated, the flexible component is tensioned, and the torque is suddenly applied to the motor, resulting in shock and vibration. Because the hydraulic coupling the pump wheel torque and speed is proportional to the square, so in the startup process, applied to the motor torque is gradually increased with the increase of speed, when the motor starting moment for pump wheel speed and low torque motor drives the pump effect, similar to the bye load starting and application, it reduces the startup shock and vibration. Engine, reciprocating pump machinery and so on, when running, produce strong torsional vibration, which makes the parts bear repeated stresses, and makes the support and base resonate, resulting in serious consequences. Hydraulic coupling can make use of the inertia damping effect of high-speed rotating working fluid to make the torsional vibration fail, and effectively isolate the torsional vibration between the prime mover and the working machine (load).

2) it has the function of overload protection

When the machine is running, the moving part storage large kinetic energy, of which a large part of savings in the high-speed rotation of the rotor of motor. The load is suddenly brake (brake or drive by the barrier, will have jammed) great power load. At this time, the kinetic energy of all the motion quality of the original motive and the working machine (load) is released instantaneously, doing work for the destruction of the machine parts. If a hydraulic coupling is applied, if the load is suddenly brakes, the braking is only the load itself, while the speed of the motor is no less than the speed of the peak torque, even if the speed is reduced, it will not exceed 10%. Therefore, the power generated by sudden braking is much less than that when using hydraulic couplings. It can prevent overload of motor and load and protect motor from burnout.